Leader ın Surface Protectıon From Past to Future.

Leader ın Surface Protectıon From Past to Future.

A Technology Vision

Shaped in the Field

LETOON’s journey began in 2006 with restoration projects carried out on Turkey’s significant monumental structures. These early years were not just a period of execution, but an intense learning process where the causes of surface deterioration, material behavior, and permanent damages caused by incorrect interventions were read and learned directly on the surface in the field.

This field accumulation formed the basis of LETOON’s analytical approach, which treats every surface not merely as an aesthetic shell but as a readable dataset with a history, structural character, and environmental loads. The experience gained in the field clearly revealed that errors made in restoration processes mostly stem from incorrect diagnosis and uncontrolled intervention, rather than execution.

The most critical realization gained during this period was:

Incorrect cleaning and incorrect surface preparation do not restore the structure; they destroy history.

This truth became the starting point for LETOON to adopt reversibility, respect for the surface, and measured intervention as a fundamental principle in its restoration philosophy.

LETOON DNA – Expertise Shaped in the Field

“LETOON’s foundations were laid on the scaffolding and directly inside the material of Turkey’s most valuable monumental structures. For us, this beginning was not just a restoration application; it was a grand experimental laboratory where we deciphered the language of the surface, analyzed the source of deterioration, and determined the needs of the technologies we would produce in the future.”

- Correct Diagnosis: Seeing surface deterioration not just as a result, but as a dataset to be solved.

- Field Reality: Ensuring the solutions developed in the laboratory are fully compatible with the reality in the field (weather conditions, surface structure, application difficulty).

- Craftsman-Engineer Bridge: Combining traditional construction craftsmanship with modern engineering discipline and world-class technologies.

LETOON DNA – What is Field Experience?

Field experience is not just about execution.

- It is learning on-site why the surface deteriorated,

- How incorrect intervention left permanent damage,

- And which decision is irreversible.

For LETOON, the field is not a construction site; it is a decision laboratory.

Technology Revolution in Restoration:

IBIX Micro Sandblasting

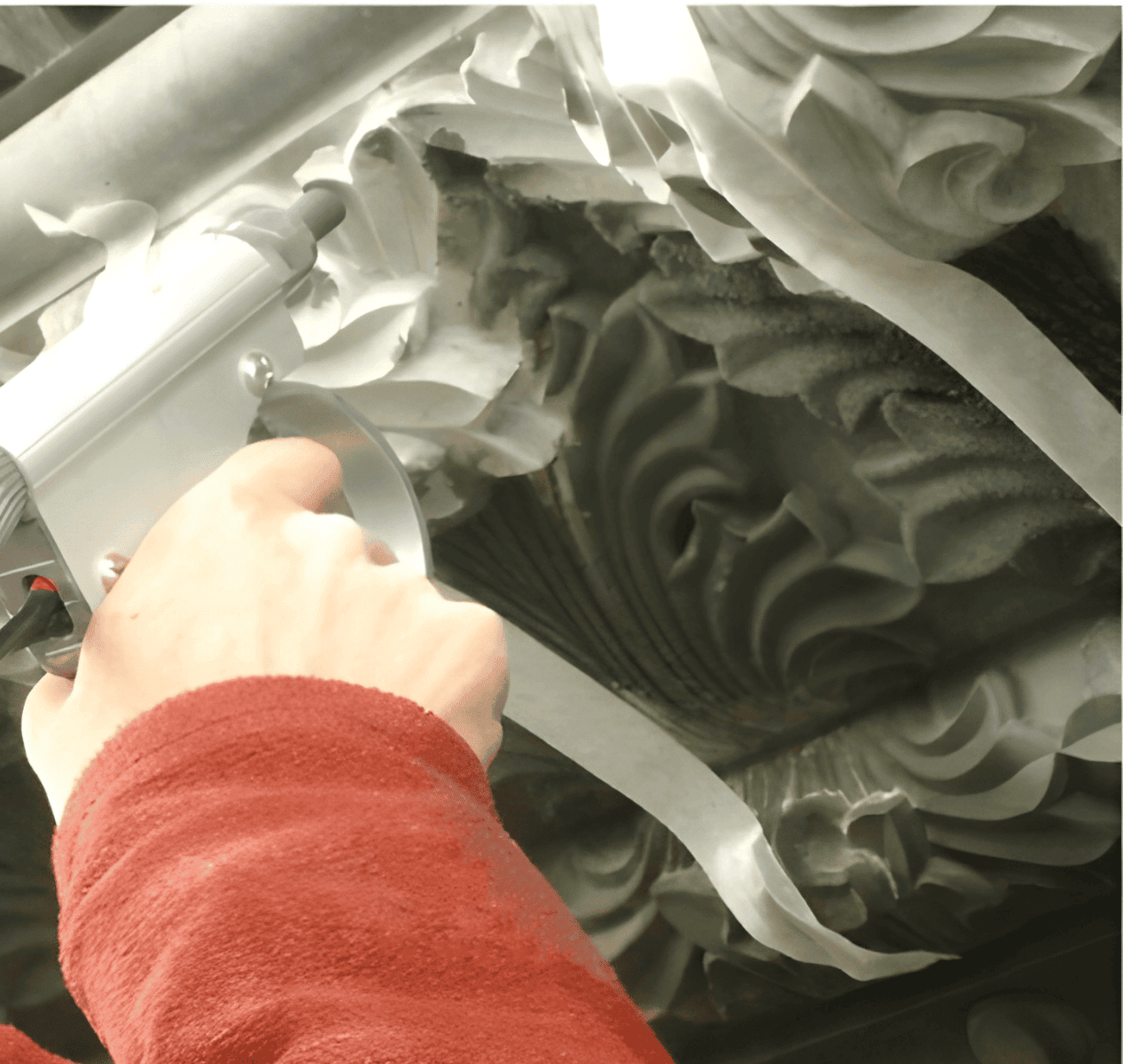

Intense field experience clearly demonstrated that traditional cleaning and surface preparation methods carry high risks and are insufficient when sensitive historical textures are concerned. In particular, uncontrolled pressure, aggressive abrasives, and interventions that disregard surface character were causing irreversible material loss and deterioration of the original texture.

In line with this awareness, LETOON introduced IBIX Micro Sandblasting Systems to the Turkish restoration sector in 2007 to set a new standard in restoration applications. With IBIX, a cleaning approach was adopted that preserves the physical and historical integrity of the surface and defines intervention through control and precision, rather than force.

With this technological transformation:

- Ecological Cleaning: An ecological cleaning approach was implemented where water and air are used at low pressure and in a controlled manner without harming historical surfaces.

- Precise Intervention: Controlled cleaning standards compatible with the surface character were established, preserving the original texture even on the most fragile surfaces.

- Sectoral Leadership: IBIX was presented to the sector not just as equipment, but as a scientifically based, measurable, and reproducible technology model in restoration projects.

This process clarified the fundamental principle in LETOON’s view of restoration:

Aggressive cleaning on sensitive surfaces means irreversible damage.

As the most concrete equivalent of this principle in the field, IBIX Micro Sandblasting became a critical turning point in LETOON’s technology-focused expertise journey based on intervention without damaging the surface.

LETOON DNA : On Sensitive Surfaces, The Accuracy of Intervention is Essential

What causes damage to historical surfaces is not the intensity of the application, but the intervention made with an incorrect diagnosis.

The LETOON approach is based on understanding the surface first, then intervening only at the necessary point with measure.

Instead of uncontrolled and rote cleaning methods, LETOON bases its interventions on being:

- Measurable

- Reversible

- Compatible with surface physics.

Uninformed intervention is irreversible damage.

Expertise Strengthened

with Global Technologies

For LETOON, this period represents a transformation process where knowledge and technical reflexes developed in the field were consciously combined with world standards. Over the years, high success was achieved on complex and sensitive surfaces with the technologies and methods we developed, especially in surface preparation and cleaning stages. However, when it came to long-term performance and permanent protection of applications, it was clearly observed that existing systems remained limited.

This realization led LETOON to seek solutions that not only solve today’s problems but also secure the future of the structure. This need for technologies that do not prevent the surface from breathing, are compatible with building physics, and provide long-lasting protection formed the basis for LETOON establishing strategic partnerships with KEIM, the world standard in pure mineral paint technologies, and EVONIK, offering molecular-level surface protection solutions. These collaborations marked the beginning of a new phase of expertise where field experience is strengthened by global technology.

KEIM

KEIM

World Standard in Mineral Paint

Technology: KEIM

Our field experience showed us the long-term damages of standard paints that prevent structures from breathing and form layers on the surface. To solve this problem at its root, in 2010 we became the solution partner of the German brand KEIM, the inventor of pure mineral-based potassium silicate paints.

- Silicification Technology: We introduced to Turkey the technology that allows the paint to integrate into the structure by forming a chemical bond with the substrate instead of forming a layer on the surface.

- Permanent Colors and Breathable Surfaces: We raised the quality bar in our projects with solutions that are most suitable for building physics, non-fading, and completely ecological.

- Sustainable Architecture: We initiated the era of “smart surfaces” that not only offer aesthetics but also extend the life of the structure.

LETOON DNA : If the Surface Can’t Breathe, The Structure Can’t Live

Any system that forms a layer on the surface is an enemy of the structure in the long run.

LETOON prefers solutions that chemically integrate with the structure, breathe, and are permanent.

We speak building physics, not paint.

Peak in Building Protection

Engineering: EVONIK – Protectosil

Taking our surface protection vision one step further, we signed a strategic partnership with EVONIK, one of the world’s most established chemical giants, in 2018. With Protectosil silane technology, we redefined building protection standards:

- Molecular Level Protection: We added silane-based solutions to our portfolio that wrap concrete and stone surfaces like invisible armor, stopping water and corrosion effects.

- Engineering Focused Solutions: We reinforced our identity as “Building Protection Engineering” by carrying our restoration experience to industrial structures, bridges, and modern reinforced concrete projects.

- Analytical Consultancy: With this process, LETOON evolved into an expert consultant position, not just a product supplier, matching technology with the right surface and the right detail.

LETOON DNA : We Don’t Choose Technology, We Match It with the Right Surface

For us, technology is not a product to be displayed, but a tool used in the right place at the right dose.

Therefore:

- IBIX

- KEIM

- EVONIK

Are not just brands at LETOON, but system components producing surface-specific solutions.

We Transformed Field Knowledge into Technology:

ECOTERA / BAUTERA

“At every point where standard products fell short, we designed high-performance solutions inspired by field realities.”

The technical vision developed over more than a decade with data collected from the field and global collaborations was carried to our own R&D processes in this period. Our approach, not content with merely application and supply, paved the way for the birth of two distinct brands shaped by the goal of “perfect surface performance” as a result of long-term research and development efforts.

ECOTERA offers sustainable materials focused on the preservation of cultural heritage structures with fully compatible, ecological, and breathable restoration solutions for historical textures.

BAUTERA responds to contemporary building needs with high-performance, durable, and long-lasting building technologies developed for modern architectural and industrial structures.

With this period, LETOON carried its expertise to a new level by combining its identity as a consulting seller with a manufacturing power that transforms field-fed knowledge into products and produces solutions.

“Standard products are for standard surfaces.

Special structures require special solutions.”

Why Did We Create Our Own Brands?

“For over ten years, we realized a truth in Turkey’s most challenging restoration sites and industrial projects: Standard and generic products on the market could not always provide permanent answers to the ‘specific problems’ unique to each structure. Every surface had a character, every geography had a different climatic load.”

Our Motivation to Transform Knowledge into Product:

- Synthesis of Field Knowledge with Global Technology: We blended the high technology learned from the global giants we represent with our local field experience coming from thousands of years of Anatolian building culture.

- Solutions Beyond Standards: We aimed to develop sustainable, ecological, and special formulas fully compatible with building physics in critical details where generic products fall short.

- Full Control and Assurance: To be sure of product performance at every stage of application, we combined our ‘consulting seller’ identity with the responsibility of a ‘solution-producing manufacturer’.

ECOTERA and BAUTERA are not just brands; they are concrete results of our vision to overcome impossibilities in the field with technology.

Leadership Strengthening

From Local to Global

For LETOON, this period represents the peak of the journey from local expertise to global solution partnership. Bringing together the sensitive discipline of restoration with the high performance expectations of industry, LETOON has today become a structure undertaking surface protection engineering not only of historical buildings but also of modern architecture and large-scale industrial facilities.

Sectoral Expansion

With our smart surface solutions focused on concrete protection, corrosion prevention, and energy efficiency, we develop systems that increase durability, extend the life, and guarantee the performance of contemporary structures.

E.S.P Standards (Ecological & Sustainable Performance)

We moved all solutions we developed to a corporate systematic under E.S.P Standards, which base on environmentally compatible and high-performance application. Thus, we made sustainability not a preference, but a measurable and auditable quality standard.

A Brand Beyond Borders

By carrying the field experience gained in Turkey and ECOTERA and BAUTERA product groups developed with our own R&D processes to international markets, we started positioning the LETOON signature beyond national borders in global projects. This step is the most concrete indicator that LETOON’s knowledge-based expertise now finds a universal response.

We no longer just read the surface; we develop and export world-class surface technologies.