Why Are KEIM Mineral-Based Sol-Silicate Paints Different?

Silicate Paint is a paint formed by the appropriate combination of water glass (potassium silicate), inorganic color pigments, and mineral-based fillers, which both penetrates and chemically interacts with the mineral surface it is applied to.

While organic paints simply form a layer on the surface, silicate paints become part of the surface. High-quality KEIM silicate paint systems provide unmatched performance, durability, protection, and color fastness. Buildings painted with KEIM silicate paints in the 19th century still retain their excellent appearance today.

The Town Hall in Schwyz, painted with KEIM silicate paints in 1891 and still retaining its original appearance today.

The Town Hall in Schwyz, painted with KEIM silicate paints in 1891 and still retaining its original appearance today.

What Are the Advantages of KEIM Silicate Paints?

Based on Natural Raw Materials;

The perfect combination between liquid potassium silicate used as a binder, naturally sourced mineral-based fillers, and purely inorganic paint pigments provides maximum durability and unmatched longevity in bad weather conditions.

KEIM silicate paints contain natural raw materials.

KEIM silicate paints contain natural raw materials.  KEIM silicate paints penetrate the surface as a result of silicification.

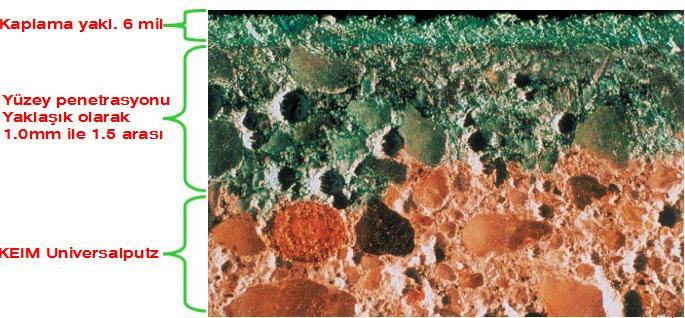

KEIM silicate paints penetrate the surface as a result of silicification.

Silicification

In KEIM silicate systems, as a result of the binder penetrating the surface, a durable and permanent bond called silicification forms between the paint and the substrate (plaster, natural stone, concrete, etc.).

Durability – Extremely Long Lasting

KEIM silicate paints possess unique durability. Numerous buildings found all over the world prove this for over 100 years. Potassium silicate used as a binder is extremely resistant to abrasion. The chemical bond formed with the surface as a result of the perfect combination of potassium silicate binder with mineral fillers is extremely strong. KEIM silicate paints do not flake off. Its binder is not damaged by UV light. It is extremely resistant to acid gases (acid rain) and industrial pollution.

Moisture Balance

High water vapor permeability is the most important criterion for average moisture balance. The extremely high water vapor permeability of KEIM silicate paints is a result of the special structure of water glass. Moisture in the building material can thus be released outwards quickly and unhindered. No moisture accumulation that could cause damage occurs between the paint and the substrate. Together with low water absorption, this combination provides optimum protection against water and frost damage.

Cleanliness

The tendency of painted surfaces to get dirty depends on static charging properties: Organic synthetic resin/silicone resin binders become electrostatically charged due to friction in the wind. In this way, they attract dirt particles from the air to themselves. At higher temperatures, these binders also exhibit thermoplastic behavior.

That is, they become ‘sticky’ and provide ideal conditions for dirt particles to adhere. KEIM Silicate paints are anti-static due to their water glass binder and do not exhibit thermoplastic behavior. Therefore, they can remain clean for a long time.

Aesthetics

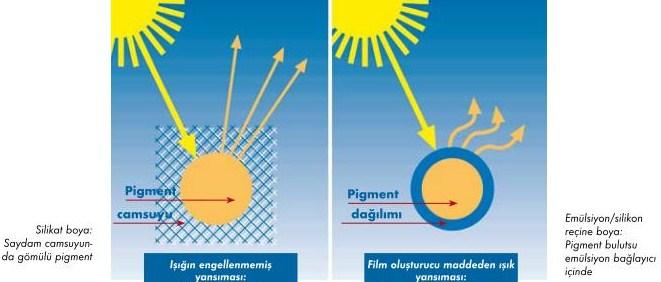

KEIM Silicate paints stand out with their unique luminosity. However, brightness here does not mean a glossy finish. The brightness of paints generally occurs through the effect of light on the pigment and its subsequent reflection. The fewer obstacles the light hitting the pigment and reflecting back faces, the brighter the color tone.

Mineral binders used in KEIM silicate paints are transparent. Light reaches the pigment unhindered. Therefore, the natural matte surface acquires an impressive and natural optical appearance. However, in emulsion or silicone resin-based paints, organic binders form a film around the pigment and affect refraction. Consequently, the original brightness of the pigment is impaired.

KEIM Silicate paints have high luminosity.

KEIM Silicate paints have high luminosity.

Color Fastness – No Fading

The color fastness of exterior wall paints is influenced by the nature of pigments and binders. UV light changes the colors of organic pigments. KEIM silicate paints contain special, high-quality, light-resistant mineral pigments. Organic binders exposed to UV light and weather conditions degrade over time. Micro-cracks affecting light refraction form, and the coating’s color tone appears grayer. Mineral binders like potassium water glass show the highest UV resistance among all binders and are completely resistant to weather conditions.

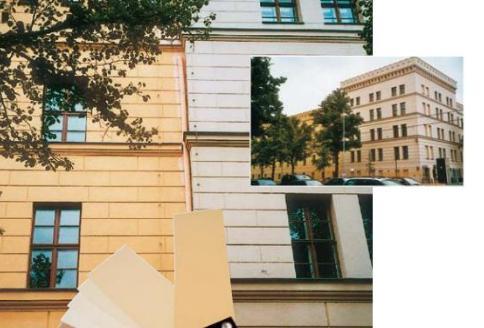

The building on the left was painted with KEIM silicate paint in 1992. The building on the right was painted with an organic pigmented paint in 1995. The picture was taken on 14.06.2004.

The building on the left was painted with KEIM silicate paint in 1992. The building on the right was painted with an organic pigmented paint in 1995. The picture was taken on 14.06.2004.

In the picture on the left, the south facade of the same building was painted with a KEIM silicate-based paint in 1974. The east facade of the same structure was painted with KEIM silicate-based paint approximately 30 years later, in 2003. There is no significant difference between the paint on the south facade, which has completed a 30-year service life, and the newly applied silicate paint.

In the picture on the left, the south facade of the same building was painted with a KEIM silicate-based paint in 1974. The east facade of the same structure was painted with KEIM silicate-based paint approximately 30 years later, in 2003. There is no significant difference between the paint on the south facade, which has completed a 30-year service life, and the newly applied silicate paint.

Health and Safety:

– They do not contain Volatile Organic Compounds (VOC).

– They do not contain toxic materials.

– They do not emit fumes or odors.

– They prevent mold.

– Non-flammable. They do not release harmful gases in case of fire.

To summarize briefly:

Radiant color tones that do not change over the long term and clean exteriors can only be achieved if the coating materials have the following properties:

- UV and acid-resistant pigments

- UV and weather-resistant binders

- Anti-static surface

- Non-thermoplastic binders

- Minimum condensation, ideal drying

- Transparent binder

KEIM Silicate paints meet these criteria in the most ideal way.