Corrosion Resistance – PROTECTOSIL® CIT

Corrosion Resistance – PROTECTOSIL® CIT

Buildings, bridges, and multi-storey car parks are among the most significant private or public investments. However, reinforcement bars inside the concrete of these structures age and rust over time. This situation causes a loss of strength. If maintenance costs are high, it becomes a very difficult case to handle. The key to protecting these structures for a long time is keeping the surface away from water and chloride ions. Even if corrosion is observed on surfaces, applicable and suitable solutions can still be found.

PROTECTOSIL® CIT is a silane-based corrosion protection system and is one of the most excellent products of EVONIK. Like other PROTECTOSIL® products, PROTECTOSIL® CIT creates a durable and long-lasting barrier due to its deep hydrophobation property. It penetrates the applied surface and reacts with the concrete. It protects reinforcements in the concrete and stops the development of corrosion.

The most effective maintenance method is one that does not require any maintenance. That’s exactly why we recommend PROTECTOSIL® CIT not only for older concrete structures but also for newly constructed structures.

Water effect is the main problem harming structures. While struggling with weathering, this situation leads to freeze-thaw cycles and salt attacks. Yet, water is only one of the reasons for deterioration. The main reason for rusting of reinforcement bars in concrete and the occurrence of mechanical regression is chlorine. Water molecules react with concrete electrostatically; because of this reaction, chlorine transmission increases and bars start to rust.

PROTECTOSIL® CIT shows a resistance effect against both chlorine and water reactions. First of all, it creates a deep barrier blocking water and prevents chlorine ions from reaching reinforcements. After that, PROTECTOSIL® CIT blocks electrolyte current, resulting in a decrease in rusting. According to independent research, three products in the market used for corrosion protection cannot be truly effective against chlorine transmission* and cannot prevent rusting.

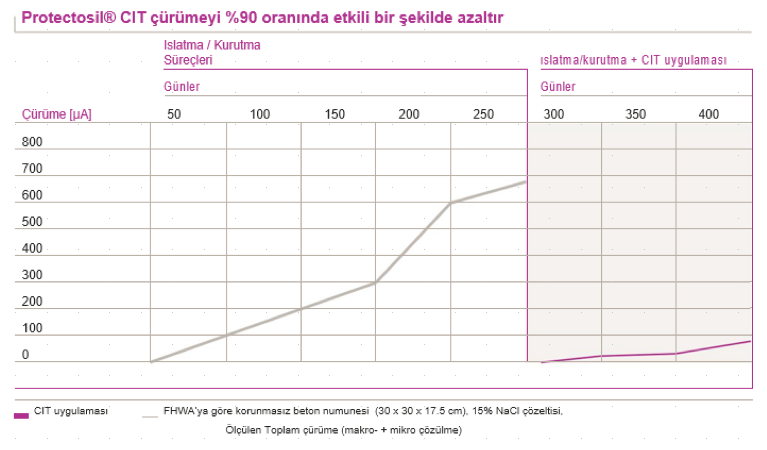

On the other hand, PROTECTOSIL® CIT effectively decreases the rusting rate according to ASTM-G109**.

* J.E. Bennett, Consultants Inc. / a research on rusting protectors due to ASTM G-109 procedures. / Report February 2004

** J.E. Bennett, Consultants Inc. / a research on Protectosil® CIT due to ASTM G-109 procedures / Report November 29, 2005

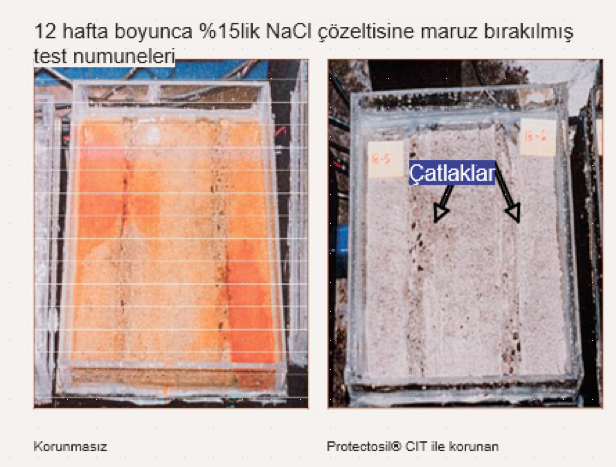

PROTECTOSIL® CIT was applied as a test on WJE Associates(1) concrete reinforcement bars which have cracks approximately 0.3 mm wide. Some specimens were protected with PROTECTOSIL® CIT before wet and dry cycling. Wet and dry procedures were performed with a 15% NaCl solution. Other specimens were left unprotected. After 12 weeks, at the end of the test, corrosion and rust could be observed on unprotected specimens. By comparison, active corrosion or rusting was not encountered on specimens protected with PROTECTOSIL® CIT.

Determining any corrosion occurring on reinforcement bars before serious and irrecoverable damage arises on the concrete is very important. The most efficient way to determine corrosion at the beginning is by measuring chlorine contamination or electrical potential/voltage difference. There are some useful in-situ measurement devices, for example, linear polarization equipment.

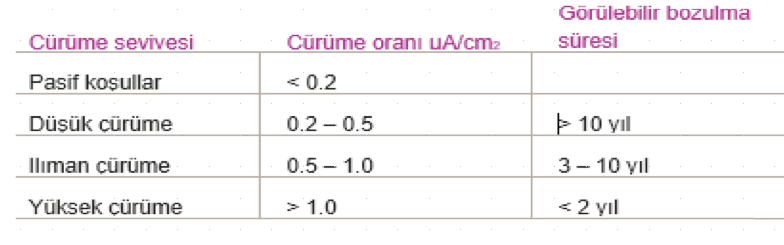

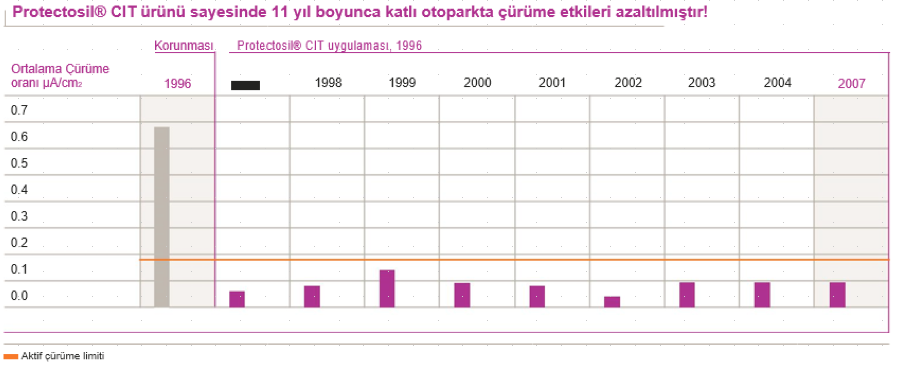

The graphics given below show the correlation between corrosion rate and periods of visible rusting. After corrosion on reinforcement bars, the application of PROTECTOSIL® CIT products is an effective solution.

Model Application: “Monroe County Multi-storey Car Parking”

Conditions are very tough in multi-storey car parks. In 1996, the corrosion rate was determined and measured via tests in the Monroe County Multi-storey Car Park, a 30-year-old building located in Pennsylvania, USA. The corrosion rate showed high corrosion occurring on reinforcement bars. If results are below 0.2 µA/cm², there is no active corrosion risk. However, in case results are above this limit, the concrete structure can be damaged.

The corrosion rate on the Monroe County Multi-storey Car Park was 0.68 µA/cm² before the application of PROTECTOSIL® CIT, posing a danger. This happens mostly in winter because of salts—ice-breakers—brought in by car tires. After the application of PROTECTOSIL® CIT, the rate mentioned above decreased to under the level of 0.1 µA/cm². Although 11 years have passed, re-application has not been required. The protection is still maintaining its performance.

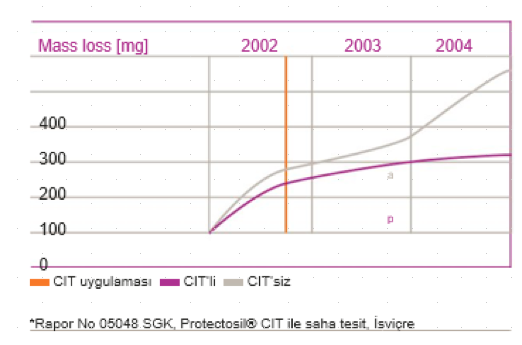

Model Application: “Application on Columns of Galleria Cianca Presella”

Sensors measured recent and potential corrosion. For a more detailed analysis of measured values, the rusted steel amount was calculated. It helped to estimate developments in corrosion damage. From the point in time after PROTECTOSIL® CIT was applied, the protected surface showed less corrosion development. Then, the protected column reached a specific passive corrosion level and stopped (tag p). Active corrosion was observed on the unprotected surface (tag a).

Sensors measured recent and potential corrosion. For a more detailed analysis of measured values, the rusted steel amount was calculated. It helped to estimate developments in corrosion damage. From the point in time after PROTECTOSIL® CIT was applied, the protected surface showed less corrosion development. Then, the protected column reached a specific passive corrosion level and stopped (tag p). Active corrosion was observed on the unprotected surface (tag a).

Products:

- PROTECTOSIL® CIT: Significantly decreases chloride-based corrosion of reinforcing steel bars in concrete due to the reaction of the active material of the cement phase with the steel surface.

- PROTECTOSIL® DRY CIT: A powder protection product. PROTECTOSIL® DRY CIT has been honored with many awards and is the first solid protection additive for reinforced concrete corrosion.

- PROTECTOSIL® WA CIT: Protects especially reinforced concrete, cast concrete, and prefabricated concrete members from chloride-based corrosion. The product dissolves homogeneously inside the concrete, and protection shrinkage decreases.